-

Prefab Construction Material

Lightweight Fast Earthquake Resistance

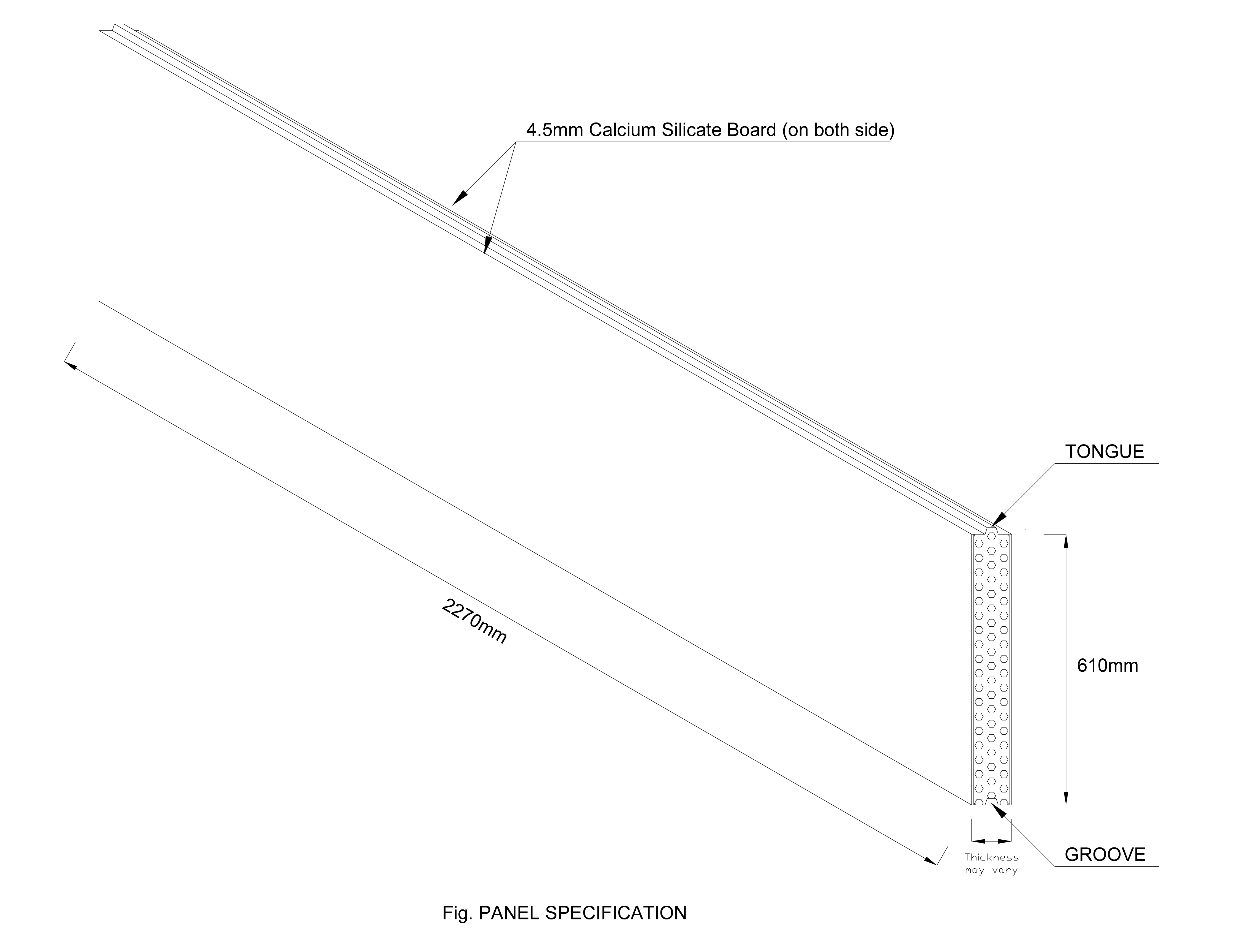

Gorkha Eco Panel is a light weight interlocking prefrabicated sandwich panel

with the composition of Non asbestos calcium silicate board,

Cement, water, Sand and Expandable Polystyrene (EPS)

-

Prefab Construction Material

Lightweight Fast Earthquake Resisitance

Gorkha Eco Panel is a light weight interlocking prefrabicated sandwich panel

with the composition of Non asbestos calcium silicate board,

Cement, water, Sand and Expandable Polystyrene (EPS). -

Prefab Construction Material

Lightweight Fast Earthquake Resisitance

Gorkha Eco Panel is a light weight interlocking prefrabicated sandwich panel

with the composition of Non asbestos calcium silicate board,

Cement, water, Sand and Expandable Polystyrene (EPS). -

Prefab Construction Material

Lightweight Fast Earthquake Resistance

Gorkha Eco Panel is a light weight interlocking prefrabicated sandwich panel

with the composition of Non asbestos calcium silicate board,

Cement, water, Sand and Expandable Polystyrene (EPS)

-

Prefab Construction Material

Lightweight Fast Earthquake Resistance

Gorkha Eco Panel is a light weight interlocking prefrabicated sandwich panel

with the composition of Non asbestos calcium silicate board,

Cement, water, Sand and Expandable Polystyrene (EPS)

-

Prefab Construction Material

Lightweight Fast Earthquake Resistance

Gorkha Eco Panel is a light weight interlocking prefrabicated sandwich panel

with the composition of Non asbestos calcium silicate board,

Cement, water, Sand and Expandable Polystyrene (EPS)